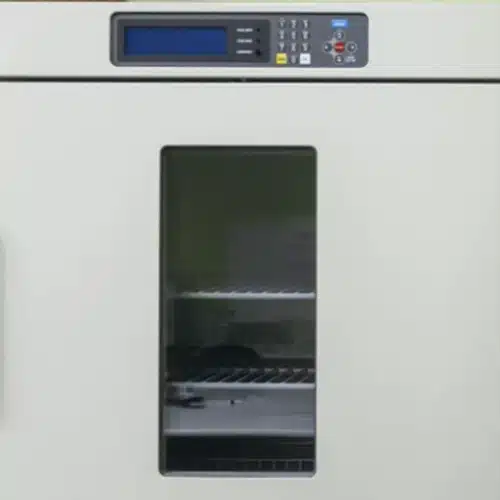

Environmental test chambers, the pinnacle of technical innovation in scientific research, revolutionize experimentation across multifaceted domains. These specialized instruments, also recognized as climatic chambers, serve as controlled environments that simulate a spectrum of conditions, facilitating rigorous testing and analysis in diverse fields.

Temperature Simulation:

One of the core functionalities of environmental test chambers lies in temperature simulation. These chambers accurately replicate temperatures ranging from extreme cold to scorching heat, allowing researchers to assess the impact of temperature variations on materials, products, and organisms. This capability is crucial in industries such as electronics, pharmaceuticals, and aerospace, where precise temperature control is paramount for performance evaluation and reliability testing.

Humidity Control:

Environmental chambers meticulously regulate humidity levels, a critical factor in numerous research scenarios. They create conditions that mimic varying humidity levels, enabling investigations into the effects of moisture on materials, electronic components, and biological specimens. Industries like agriculture, food sciences, and materials engineering rely on these chambers to evaluate the behavior of substances under controlled humidity conditions.

Light and UV Exposure:

Certain environmental test chambers integrate light and UV exposure mechanisms. These chambers facilitate studies on the impact of light and UV radiation on materials, products, and organisms. Industries such as cosmetics, materials science, and solar energy utilize these chambers to assess degradation, aging, and photochemical reactions of substances when exposed to different light spectra and UV intensities.

Altitude and Pressure Simulation:

In addition to temperature and humidity control, some advanced environmental chambers simulate altitude and pressure conditions. These chambers replicate high-altitude conditions and varying pressures, crucial for aerospace, automotive, and packaging industries. Researchers assess how materials and components perform under such extreme conditions, ensuring safety and reliability in their respective applications.

Laboratory technicians are the custodians of these sophisticated instruments, responsible for their operation and maintenance:

Precise configuration and calibration of environmental chambers according to experimental requirements are fundamental tasks undertaken by technicians to ensure accuracy and reproducibility of results.

Continuous monitoring of chamber parameters to guarantee stability during experiments is essential, as even minor fluctuations can affect outcomes significantly.

Regular maintenance routines, including sensor checks, calibrations, and equipment servicing, ensure optimal performance and extend the lifespan of environmental test chambers.

Swift troubleshooting and resolution of technical issues are imperative to minimize disruptions and maintain the continuity of experiments. For such needs Peak BioServices offers extensive support for various repair, maintenance and calibration needs.

Environmental test chambers epitomize technical excellence in scientific research by offering precise control over temperature, humidity, light, UV exposure, altitude, and pressure conditions. Their integration across various industries and the diligent work of laboratory technicians enable groundbreaking discoveries and innovation across diverse fields, shaping the future of scientific exploration and technological advancement.